Tecnologia em Supply Chain

Produtividade, acurácia e segurança no seu centro de distribuição

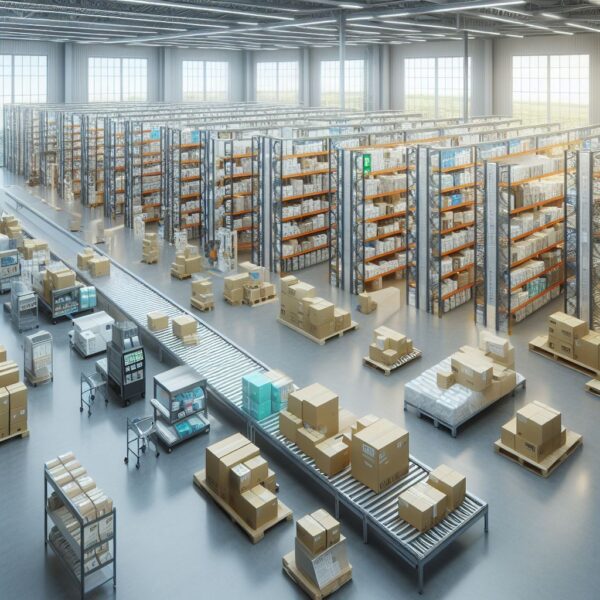

Produtividade, acurácia e segurança

no seu centro de distribuição

Conheça o sistema de gerenciamento de armazém da Delage, eleito duas vezes o Melhor WMS do Brasil. O WMS Delage® Rx é uma solução aderente a todos os elos da cadeia de abastecimento: indústria, distribuição, operação logística, varejo e e-commerce. O software conta com um completo conjunto de funcionalidades, além integração nativa com sistemas automáticos e com os principais ERPs do mercado. Com WMS Delage® Rx, você tem informações em tempo real, gerando métricas importantes para o controle, a avaliação do desempenho e o planejamento de ações futuras.

Clique e saiba maisO AccuScheduler® é uma moderna e exclusiva solução 100% Cloud voltada para a área de Supply para executar o planejamento e a gestão do agendamento de entregas/recebimentos nas empresas. A plataforma é colaborativa, integrando a sua empresa com seus fornecedores e transportadores e centralizando em um único lugar todas as informações referentes ao recebimento. Além disso, conta com funcionalidades que garantem mais segurança, maior previsibilidade e uma drástica redução de custos.

Clique e saiba maisO OMS Maestro é uma solução 100% SaaS desenvolvida para dar suporte à logística omnichannel, conectando produtos, estoques e entregas em um único lugar. A plataforma integra o seu negócio a todos os atores do comércio digital (como VTEX, marketplaces e apps) e permite uma gestão eficiente para que o seu cliente tenha um atendimento ágil e unificado. Com o OMS da Delage, você não precisa pagar taxas de comissão pela orquestração de pedidos e pode escalar o seu negócio com liberdade e autonomia.

Clique e saiba maisConheça o sistema de gerenciamento de armazém da Delage, eleito duas vezes o Melhor WMS do Brasil. O WMS Delage® Rx é uma solução aderente a todos os elos da cadeia de abastecimento: indústria, distribuição, operação logística, varejo e e-commerce. O software conta com um completo conjunto de funcionalidades, além integração nativa com sistemas automáticos e com os principais ERPs do mercado. Com WMS Delage® Rx, você tem informações em tempo real, gerando métricas importantes para o controle, a avaliação do desempenho e o planejamento de ações futuras.

Clique e saiba maisO AccuScheduler® é uma moderna e exclusiva solução 100% Cloud voltada para a área de Supply para executar o planejamento e a gestão do agendamento de entregas/recebimentos nas empresas. A plataforma é colaborativa, integrando a sua empresa com seus fornecedores e transportadores e centralizando em um único lugar todas as informações referentes ao recebimento. Além disso, conta com funcionalidades que garantem mais segurança, maior previsibilidade e uma drástica redução de custos.

Clique e saiba maisO OMS Maestro é uma solução 100% SaaS desenvolvida para dar suporte à logística omnichannel, conectando produtos, estoques e entregas em um único lugar. A plataforma integra o seu negócio a todos os atores do comércio digital (como VTEX, marketplaces e apps) e permite uma gestão eficiente para que o seu cliente tenha um atendimento ágil e unificado. Com o OMS da Delage, você não precisa pagar taxas de comissão pela orquestração de pedidos e pode escalar o seu negócio com liberdade e autonomia.

Clique e saiba mais